The history of the Telangana movement has been distorted to project that only one family participated in it, said Chief Minister A. Revanth Reddy on Friday.

Stating that many sections participated in the Telangana movement, he called for more books to present the true history of the movement.

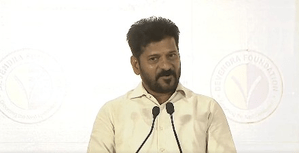

The Chief Minister was speaking at an event to release ‘Vijaya Telangana’, a book written by former minister T. Devender Goud.

Taking a dig at the family of former chief minister and Bharat Rashtra Samithi (BRS) President K. Chandrasekhar Rao, Revanth Reddy alleged that they tried to project the history of the Telangana movement in their favour.

“The sacrifices of the students and youth who participated in the Telangana movement should be included in the history. KCR family tried to write the history that one person, one family, one political party is Telangana,” he said.

The Chief Minister stated that Devender Goud tops the list of leaders he admired the most. He praised the former minister for writing a book on the history of the Telangana movement from the people’s perspective.

He recalled that the decision taken by Devender Goud to launch a political organisation for the cause of Telangana was courageous. Devender Goud was the second-in-command of the party at that time.

“Devender Goud sacrificed a good career and came out with the Telangana flag. He conducted padayatra to give a strong message that Telangana will be prosperous only with the waters of river Godavari. The then rulers took up the Pranahita-Chevella project after Devender Goud’s padayatra,” the Chief Minister said.

He also noted that during the Telangana movement, youth wrote TG not only on their vehicles. Devender Goud wrote TG on the walls during the movement.

The Chief Minister claimed that respecting the aspirations of the people, the Congress government changed TS to TG soon after coming to power and declared ‘Jaya Jayahe Telangana’ as the official song of the state. “These were all people’s ideas and not mine,” he said.

He pointed out that the government announced a house and Rs 1 crore for nine Telangana activists who sacrificed everything during the Telangana movement.

Stating that the absence of people like Devender Goud in active politics is an irreparable loss for Telangana, Revanth Reddy said leaders who uphold values should join politics.